New OOI Coastal Surface Mooring Design

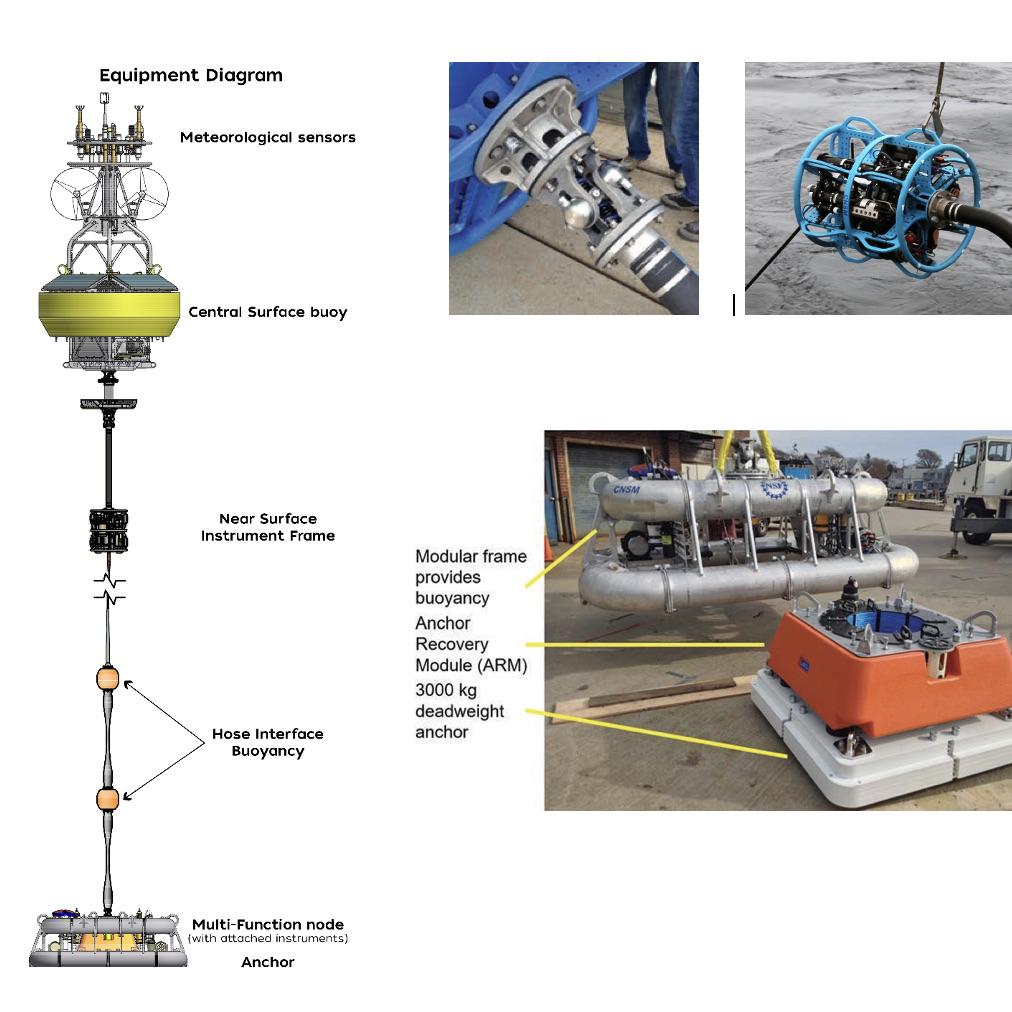

The OOI Coastal Surface Moorings (CSMs) showcase a variety of innovative mooring technologies. Although the design concepts were initially developed as elements of other mooring systems, they were brought together for the first time on the OOI CSM. A recent paper by Peters et al. (2022) describes three areas where new design concepts were particularly impactful: (1) components at the interface between the surface buoy and mooring riser, (2) mooring riser components, and (3) an integrated seafloor anchor and instrument frame. These components work together to provide mechanical integrity for the mooring as well as mounting points for instrumentation and a reliable electrical pathway for the transmission of power from the surface to the seafloor and data from the seafloor to the buoy (Figure above).

Components comprising the buoy-to-riser interface include a universal joint, an electro-mechanical (EM) chain, and a Near Surface Instrument Frame (NSIF). The universal joint, at the buoy base, reduces the translation of buoy pitch and roll motion into bending moments at the top of the mooring riser. The EM chain, a conventional chain wrapped with helically-wound conductors and encapsulated in urethane, provides a flexible strength member between the buoy and the NSIF. The NSIF provides a mounting point for instruments and a mechanical transition from the EM chain to the EM cable.

Components along the mooring riser include the EM cable, EM stretch hoses, and distributed buoyancy elements between stretch hoses. The EM cable employs a wire rope strength member mechanically terminated with a swaged fitting. A molded urethane strain relief boot at the upper end of the cable interfaces with the NSIF bellmouth. The lower termination assembly provides strain relief and a cavity for integration of underwater connectors. The EM stretch hoses were initially developed in the 1990s by WHOI engineer Walter Paul. A novel, multi-layer construction technique was developed for OOI to enable a 24-conductor stretch hose. Hose lengths from 9 to 30 m are employed on OOI moorings. Each hose has a breaking strength of over 10,000 lb and stretches to over twice its original length to provide variable mooring scope and reduction of peak dynamic loads.

At the buoy base is an integrated anchor and instrument frame assembly called the Mult-Function Node (MFN). The MFN frame is a buoyant structure made of air-filled aluminum pipe, configured to allow the mounting of instruments, data loggers and batteries. The MFN is weighted to the seafloor with an anchor assembly that sits in the center of the frame, connected with dual acoustic releases. The anchor assembly consists of a flat-plate anchor below a foam buoyancy element that contains an internal spool with several hundred meters of synthetic line. The buoyancy element is connected to the anchor with dual acoustic releases. This system allows for mooring and anchor recovery in three stages: First, the MFN is separated from the anchor and the mooring riser is recovered. Next, the buoyancy element is released from the anchor allowing it to rise to the surface while offspooling line. Finally, the anchor is hauled using the synthetic line.

This unique combination of design elements creates a mooring system capable of housing and powering complex instrument systems, transmitting data in near real-time, and contributing to the long-term reliability of the OOI Coastal Surface Moorings in the challenging environment of the continental shelf.

Peters, D.B, J.N. Kemp and A.J. Plueddemann (2022). Coastal Surface Mooring Developments for the Ocean Observatories Initiative (OOI). Marine Technol. Soc. J., 56(6), 70-74. doi.org/10.4031/MTSJ.56.6.2.