R/V Neil Armstrong in Drydock while OOI Team Onboard

The fact that the R/V Neil Armstrong was out of the water on blocks at the Deytens Shipyard in North Charleston, SC, didn’t deter the Ocean Observatories Initiative (OOI) Coastal and Global Scale Node (CGSN) Team members from loading equipment and setting up laboratories for the first at-sea test deployment for the Coastal Pioneer Array in its new location in the Southern Mid-Atlantic Bight. Woods Hole Oceanographic Institution (WHOI) Port Engineer Hank Ayers helped make this dual operation possible. Ayers has been handling logistics for the Armstrong for 10 years. Over the course of time, he’s developed a knack for multi-tasking, and keeping on schedule and budget, while keeping the 238-foot Armstrong in tip top shape.

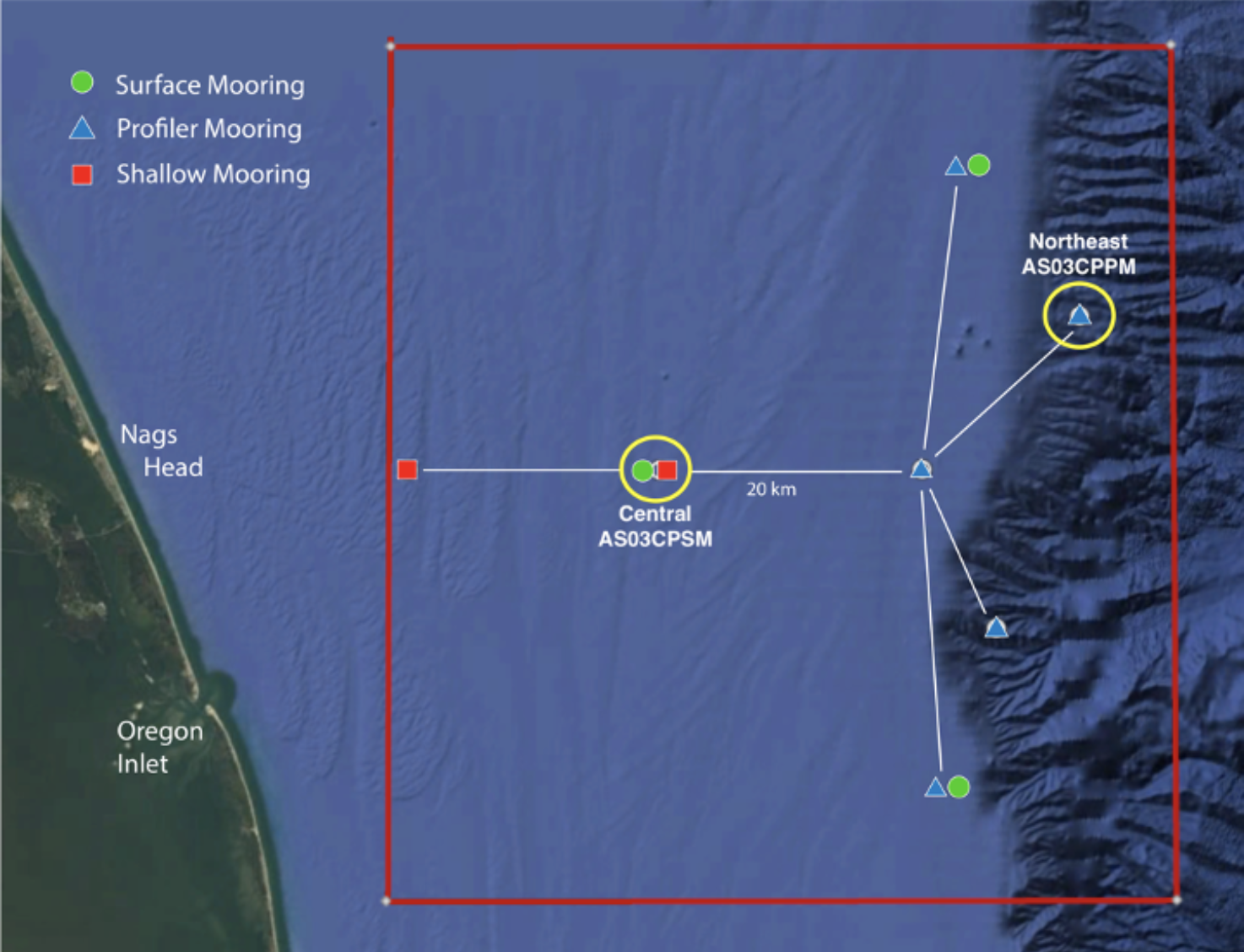

Looking at the Armstrong’s at-sea schedule, Ayers arranged for a regulatory drydock period prior to the Pioneer test deployment expedition near the array’s test deployment off the coast of Nags Head, NC. (See figure to right). Regulatory drydock checks are required about every two and a half years for inspections mandated by the US Coast Guard and the American Bureau of Shipping. While in drydock, the Armstrong underwent inspections of the propeller shaft, 17 sea chest valves were checked for condition and wear, the port and starboard anchor chains were replaced, and about 10 percent of the ship’s hull was repainted most of this along the waterline, where it is most susceptible to wear and marine growth, while other sections were touched-up as needed. Other regular maintenance tasks were also completed while the crew was in port.

Ayers explained the complexity of getting a huge vessel that weighs 2641 tons with a 50-foot beam into drydock so the keel can be inspected. “The ship is steered into a big basin with a movable wall at one end. The goal is to have the ship land on top of blocks so when the water is pumped out, it will be securely in place. It’s a delicate process. There’s a ball that floats up at the bow when the ship is in the right position. Once aligned, the crew keeps the ship centered and in position. A diver is also in the basin to make sure that once the ship gets close to the blocks there are no problems down there. Once the ship is in place on the blocks, the water is drained out.”

The Armstrong was out of the water for 20 days. The Pioneer At-Sea Test team arrived on February 16 to begin the unusual process of mobilizing for the expedition while the ship was technically on land. The shipyard is equipped with huge cranes needed to load the 8000+ pound moorings onto the stern of the ship. Under normal operating conditions, the cranes on the ship would be used to load the equipment onboard.

Said CGSN Instrument Lead Jennifer Batryn who helped with the mobilization, ““It was definitely weird seeing the Armstrong out of the water. It’s a very different perspective than most people are used to seeing for the ship and was especially interesting to observe given OOI uses the Armstrong for a number of our cruises. Other than that, once we were on the ship while it was still in drydock, it really didn’t feel that much different. The ship was very stable and we went through the normal operations of getting the equipment onboard and ready for departure.“

Once loaded, some of the CGSN team headed home to Woods Hole Oceanographic Institution, while a team of nine WHOI engineers and scientists stayed onboard to execute the test deployments.

The process of refloating the ship commenced on February 21 with the filling of the drydock. It took about 6 hours and 134 million gallons of water to raise the Armstrong in the dock to sea level and ready for departure. The movable wall was taken out and the Armstrong maneuvered over to a nearby pier to continue to get ready for sea and OOI work.

Added Ayers, “The Armstrong is a beautiful, capable ship. When she’s out of the water, you get a sense of her size and capabilities. It’s always a wonderful sight.” And one that won’t happen for a while. Armstrong’s next scheduled drydock is in 2025, so for now, the ship is in good working order and ready to continue its job as a scientific workhorse.

Videos credit: Rebecca Travis © WHOI.