OOI Engineers Develop New Rechargeable Lithium-ion Battery Pack

By John Lund, Research Associate, Woods Hole Oceanographic Institution

The final deployment of the Coastal Pioneer Offshore Mooring (CP04OSPM-00016) was the first deployment of a prototype rechargeable lithium-ion battery pack. The deployment was a success with the battery pack providing power throughout the entire 6.5-month deployment.

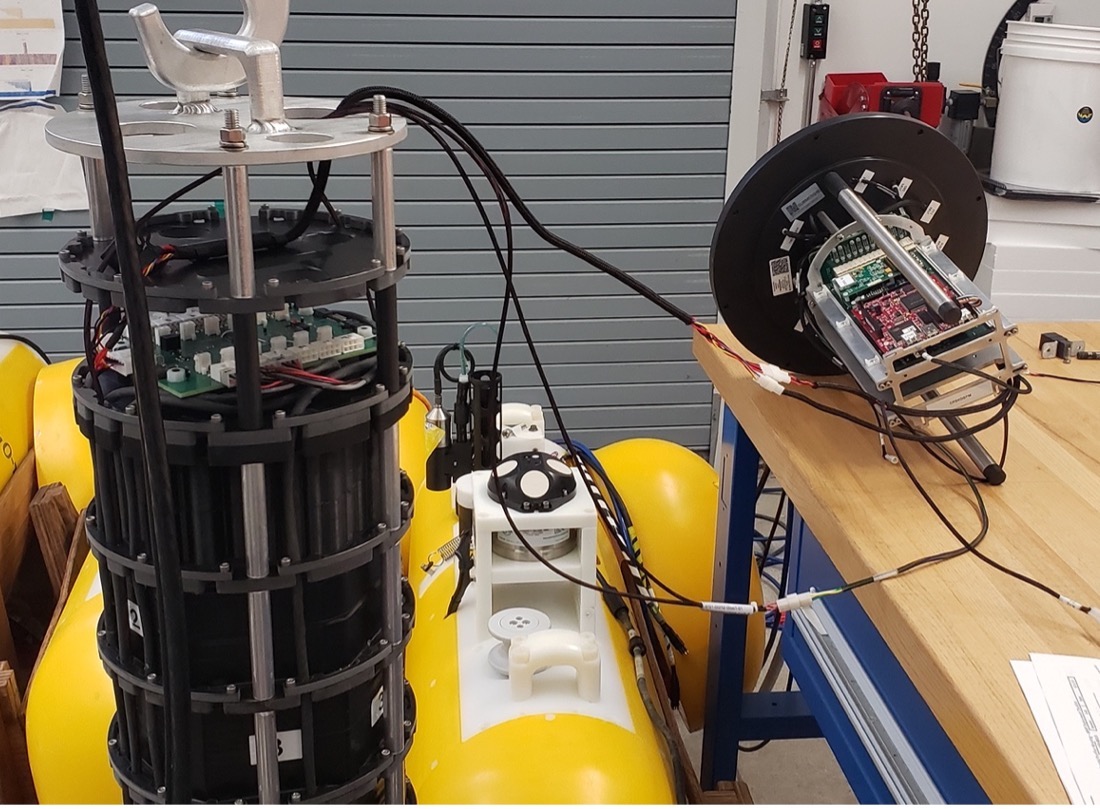

Working with Mathews Associates Inc. the OOI engineering team developed a drop-in replacement lithium-ion rechargeable battery pack to replace the original one-time use alkaline packs. Each alkaline pack consists of 72 D-sized batteries that are fabricated into a hexagonal assembly. Nine of these battery packs are fitted into a buoy battery chassis that fits inside the buoy well. The packs are wired together in parallel to provide the required voltage to power the computer (buoy controller) responsible for telemetry and data-logging.

Pioneer moorings are nominally deployed for 6-month intervals. Variability in ship scheduling requires that the buoys be capable of operating for 7+ months. The alkaline battery chassis was designed to fit enough packs to power the buoy for the planned duration and or until the recovery ship arrived.

The Offshore mooring was selected to be a test mooring because it is one of the deeper moorings in the New England Shelf (NES) Pioneer Array and as such logs and transmits more data than a shallower mooring. The larger data sets mean that the buoy up-time, and therefore power usage, is greater than one in shallower water so this would be a tougher test of the lithium-ion packs.

Although there is an increased cost to purchasing the initial set of lithium batteries there are many advantages to the rechargeable batteries. Because the alkaline packs are conservatively sized for the deployment there is often a considerable amount of power remaining in the packs when they are recovered, yet this remaining power is insufficient for another full deployment, and new batteries must be used. The chief benefit of the rechargeable batteries will be to keep the one-time use alkaline packs from going to the landfill (~1 ton per year). There is also a considerable labor savings of not having to deconstruct and reload the chassis frames with replacement batteries. Our calculations indicate that we will break in terms of procurement cost compared to alkaline batteries in approximately six years and that the lithium-ion batteries have enough charge cycles (500) to last the duration of the program. With any luck these may be the last batteries we need to purchase for the Profiler Moorings!