Biofouling Mitigation from Top to Bottom

OOI operates its arrays in challenging environments. At the sea surface, sea lions find the buoys attractive resting spots. At the bottom, instruments must collect data under varying temperatures at intense pressures. And, then throughout the water column’s photic zone is marine growth. Marine life finds OOI’s instrumentation and arrays irresistible, where it attaches and grows like gangbusters.

The folks who keep OOI’s arrays operational explain the conditions this way:

“Putting any kind of instrumentation – electrical or scientific instrumentation – in the water for a year or more at a time is always a challenge, said Dana Manalang, Engineer, OOI Regional Cabled Array (RCA). “It’s a harsh environment due to the high pressures and salt water so getting systems to operate sub-seas is the largest challenge we face.”

“It’s a challenging place to work,” concluded Coastal Endurance Array Project Manager Jonathan Fram, “And, we are very thankful to have the opportunity to make stuff that can survive in just about any marine environment.”

So how do they do it? OOI engineers develop creative ways to tackle the many challenges, particularly in terms of some of the peskier, persistent ones like keeping marine growth, referred hereafter as biofouling, at bay.

Diaper cream as a solution

Coastal and Global Scale Node (CGSN), Coastal Endurance, and RCA team members have implemented novel ways to minimize and in-situ clean marine growth on sensors, gliders, and components of the arrays that spend up to 12 months in the water.

One such novelty is the application of diaper cream. An inexpensive and convenient form of zinc oxide, diaper cream, has been used for decades as a marine anti-foulant, with moderate effectiveness. . “Its application for oceanographic equipment goes back at least to the 1990’s, and is considered non-toxic relative to other concoctions, “ explained Peter Brickley, CGSN Observatory Operations Lead. Other anti-fouling scheme exist, but some are expensive, some add weight, while others take too long to apply and don’t fit into the team’s operational deployment plans.

“The only downside is that diaper cream has be to done onboard right before deployment, or it’s a mess,” he added.

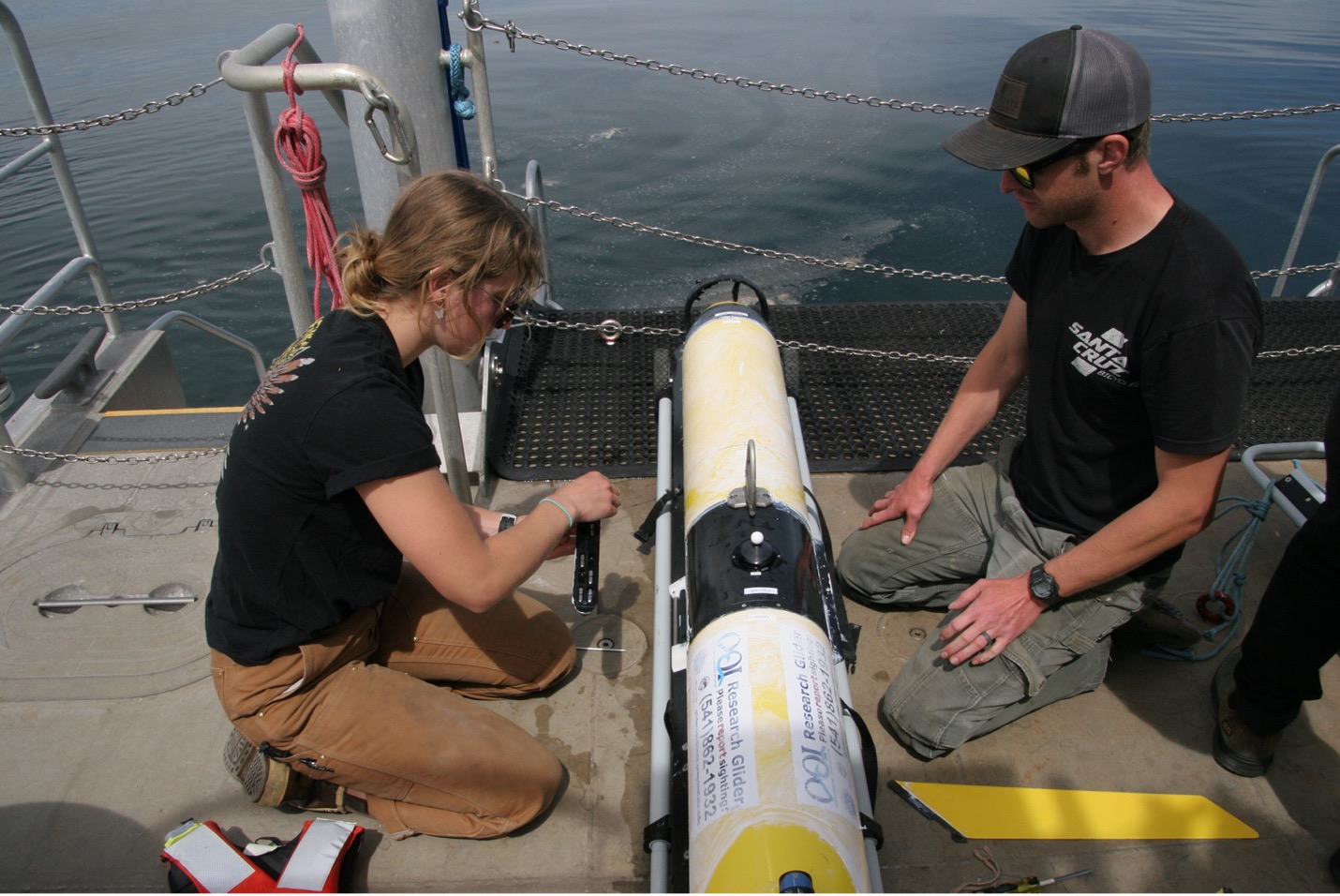

Coastal Endurance Project Manager Jonathan Fram said, “One key issue is that gliders are made of aluminum, so we can’t use copper-based antifouling material on them. Diaper cream is zinc-based, so it won’t corrode gliders’ aluminum.” The Coastal Endurance Team regularly applies diaper cream to its glider fleet, with measurable success. “Gliders with barnacles on them can’t swim straight or efficiently. The diaper cream provides a protective coating to which marine growth cannot readily adhere. It helps keep our gliders moving easily through the water and reporting data.”

After being successfully tested on gliders, the Coastal Endurance Array and RCA teams then tried the protective diaper cream as an option to keeping acoustic transducers on the arrays clean, as suggested by the vendor. An acoustic transducer is an electrical device that vibrates, producing sound waves in water. OOI uses transducers in both echosounders and hydrophones. Here, too, the diaper cream proved to be an inexpensive and effective biofouling mitigation measure.

Addition of UV lights

Putting ultraviolet lights in the water to discourage marine growth is another proven biofouling mitigation measure. Early on, the Coastal Endurance team deployed two oxygen optodes, which measure dissolved oxygen, side-by-side at seven meters depth on the Oregon Shelf Surface Mooring with a UV light pointed at one of them. Data from the two sensors tracked each other for six weeks after which the unprotected sensor fouled. Within weeks, there were daily afternoon spikes of up to twice the oxygen level of the protected sensor, with slightly lower measurements than the unprotected sensor at night due to respiration of the biofilm. Since this test, optodes are regularly deployed with UV lights to aid their operation. (Annotations of OOI moored oxygen data note when a UV light was not operating with it.)

Following the success of the UV-light on dissolved oxygen sensors, the CGSN team tested this antifouling measure on a moored Coastal Pioneer Array spectral irradiance (SPKIR) sensor, which measures the amount of light energy that reaches a surface. The testing was conducted with Sea Bird Scientific, the SPKIR vendor. The vendor confirmed that the UV light did not damage the instrument’s optics nor did it interfere with its light measurements. After this confirmation and positive result, UV lights are now used on all SPKIR sensors on Surface Moorings, Coastal Surface Piercing Profilers, and uncabled digital still cameras moored at less than 70 meters. The teams adjust the on/off cycle of the UV lights so that biofouling is prevented without damaging the sensors, interfering with measurements, or using too much power.

Lens-Cleaning Brushes

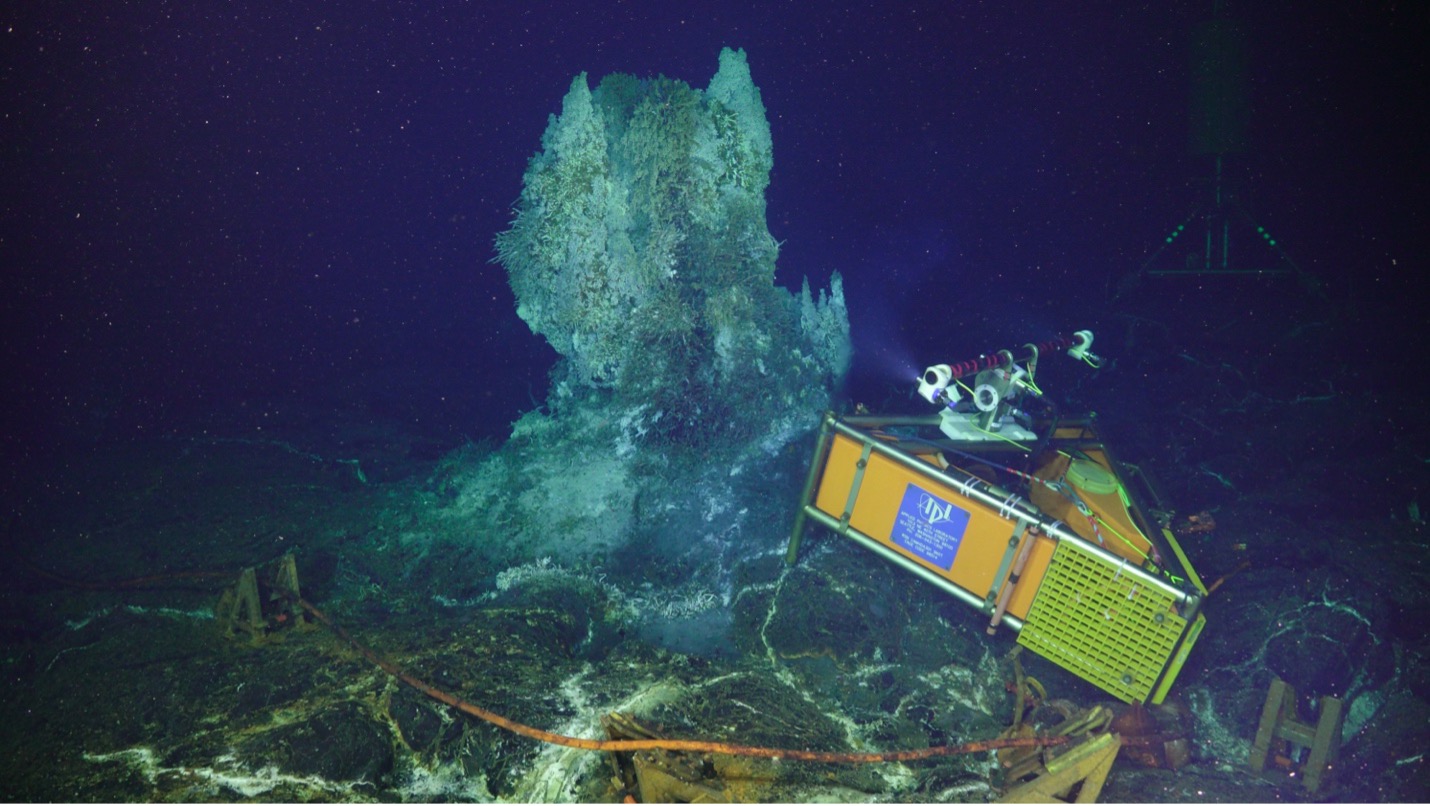

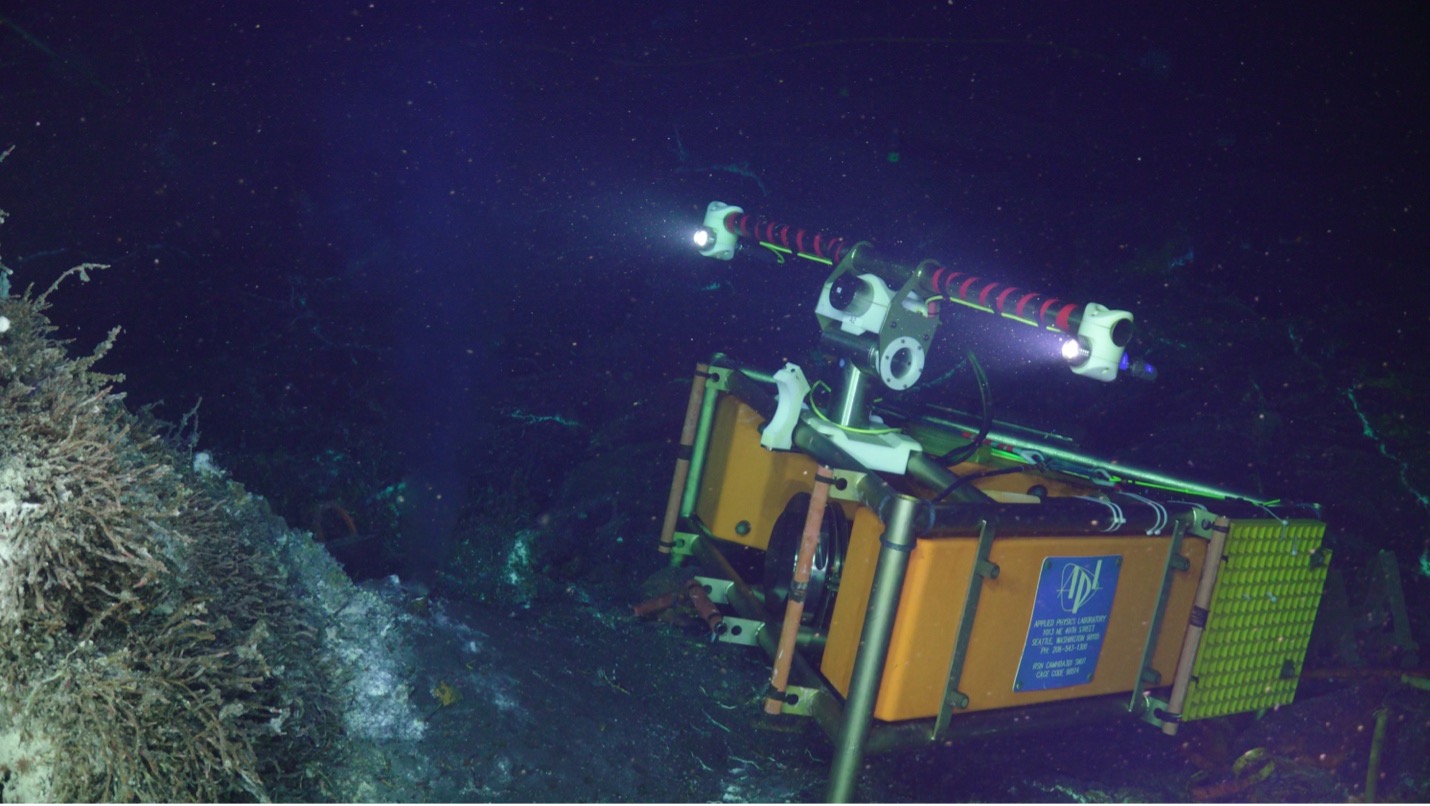

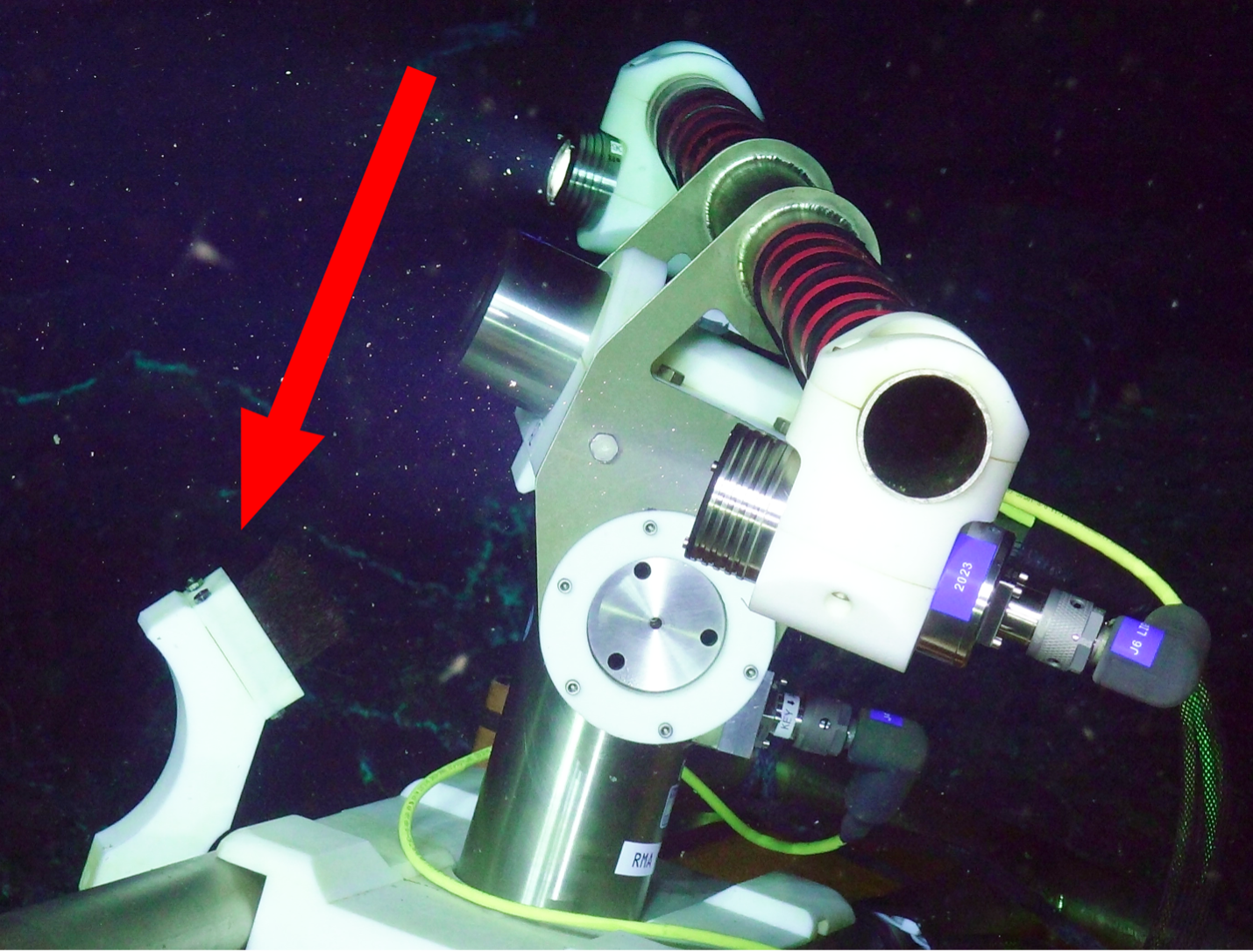

The RCA also has adopted novel ways to deal with biofouling on the Pacific Ocean seafloor. RCA operates and maintains a high-definition (HD) video camera (CAMHD) at the base of an actively venting hydrothermal chimney called “Mushroom” (see below) in the ASHES vent field of Axial Seamount Caldera. Live HD video of this > 4-m high chimney and surrounding seafloor is streamed to shore on an automated schedule for 14 minutes at 3-hour intervals, with longer non-stop monitoring for 24 hours twice a month and 72 hours at the beginning of each month.

The scene is fully scanned with programmable pan, tilt, and zoom functions of this instrument, which provides detailed imagery of the high-temperature water spigots, sea spiders, lipets tube worms and other biota covering both the chimney and surrounding lava-covered seafloor.

Unfortunately, such live subjects, microorganisms, and other organic/inorganic processes often deposit a film on the camera lens which interferes with visualization. To ensure optimal clarity of HD video between site maintenance visits during annual RCA operation and maintenance expeditions, an automated lens cleaning protocol using a simple brush, installed on the instrument’s frame in the front of the lens has been instituted.

This programmed event occurs three times a month and tilts the camera down and pans it left and right, allowing the brush to gently clean the lens. The video streaming and lens cleaning schedules can be optimized remotely from shore by RCA personnel to provide the highest scientific and educational value from the HD video.

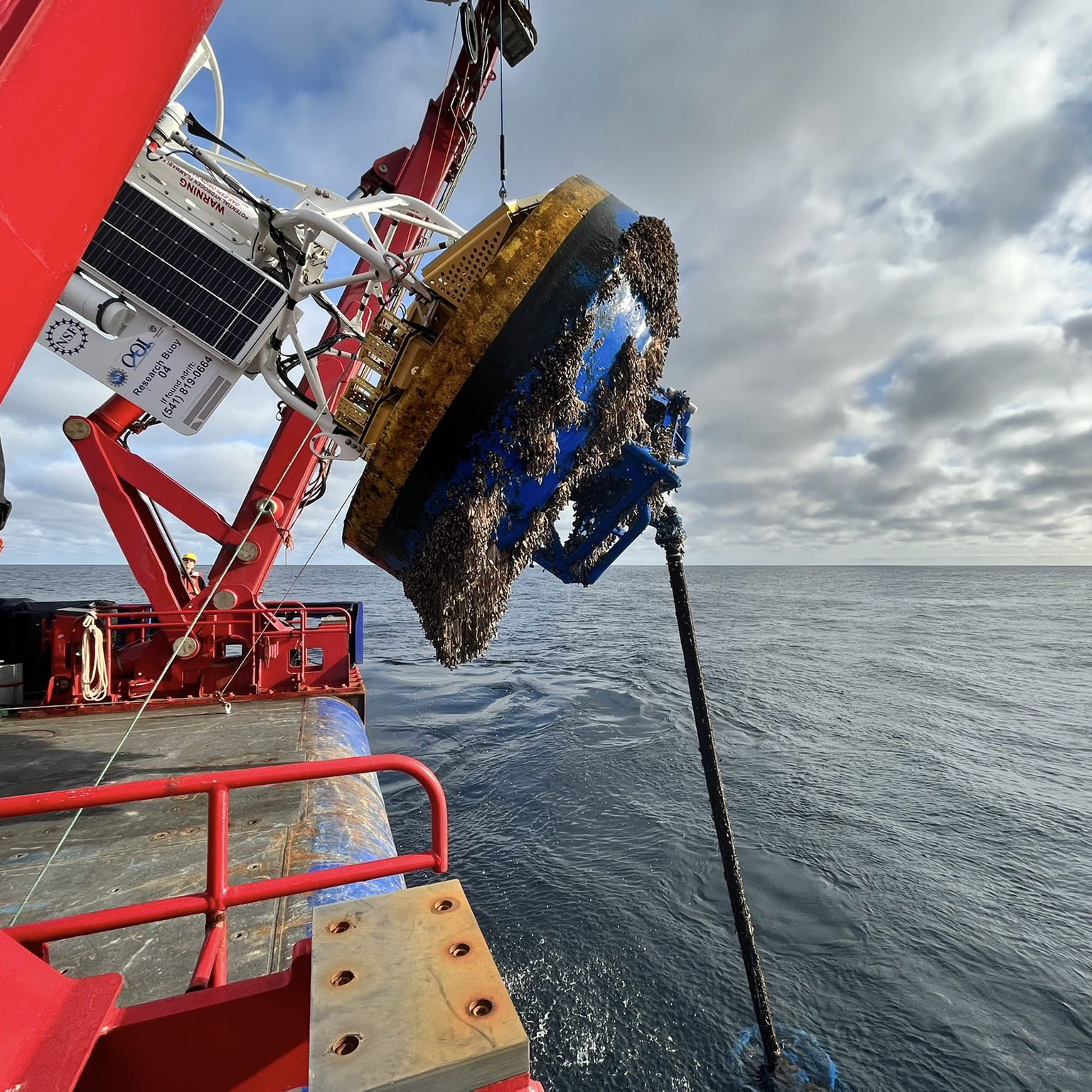

Eco Anti-fouling paint

Ever wonder why OOI’s buoys are painted blue? This eco-friendly paint serves the same purpose as diaper cream and UV lights—to minimize marine growth on the buoys and its metal components. The teams use a commercially available water-based and copper-free anti-fouling paint. Once recovered, the CGSN and Coastal Endurance Array components are taken apart and refurbished so they function like new once ready to be redeployed. All metal components and float areas are cleaned and receive a fresh coat of paint in the hope of diminishing their attractiveness to life below the surface.