Biofouling Preventatives on Surface Mooring Instrumentation

During the first leg of Pioneer 21, the team recovered the three surface moorings deployed in the Mid-Atlantic Bight (MAB) region, including the associated Multi-Function Nodes (MFNs) and Near-Surface Instrument Frames (NSIFs). Upon recovery, the state of the instrumentation at these sites showcased the effectiveness of biofouling mitigation strategies employed during this past year long deployment in the MAB region.

Biofouling — the accumulation of marine organisms such as algae, barnacles, and tube worms — is a challenge for sustained ocean observations. Unchecked growth can obstruct sensor faces, degrade data quality, and damage equipment. While complete prevention is rarely possible over extended deployments, targeted mitigation techniques can significantly limit biological overgrowth on critical sensing surfaces.

The following examples illustrate both the extent of biofouling on non-critical surfaces and the relative success of antifouling methods used to protect sensor interfaces:

The seven white wavelength band sensing points of the Spectral Irradiance sensor (https://oceanobservatories.org/instrument-class/spkir/) in this image had been kept free from biofouling by a neighboring UV light that had been carefully positioned to illuminate the sensing region during throughout deployment. (c): Sawyer Newman, WHOI

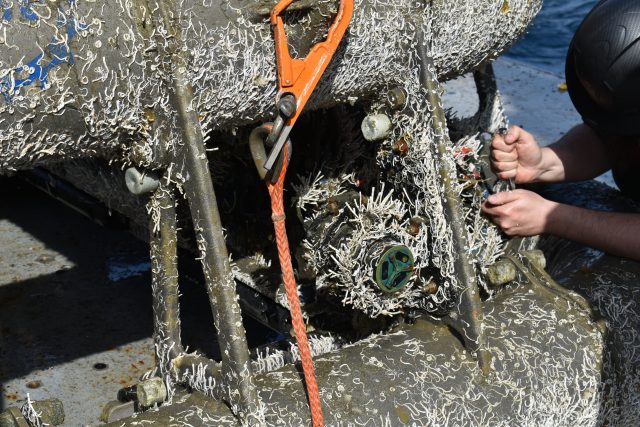

This photo shows a Fluorometer (FLORT) (https://oceanobservatories.org/instrument-class/fluor/) mounted to the SOSM-1 MFN used for turbidity sensing. This sensor face was kept clear from fouling by a rotating wiper. In contrast, tube worm growth is visible on non-sensing portions of the FLORT and adjacent structural elements of the MFN. (c): Sawyer Newman, WHOI

Zinc oxide cream (specifically, commercial diaper rash cream) was applied to the sensor faces of ZPLSCs (https://oceanobservatories.org/instrument-class/zpls/) prior to deployment. This image shows tube worm growth on the non-sensing parts of the ZPLSC, while the round sensing area, coated with zinc oxide, remained clear of biological growth. (c): Sawyer Newman, WHOI

These observations underscore the importance of selecting and applying biofouling prevention strategies tailored to each sensor’s operational context and sensitivity. The recovery and evaluation of these assets offer critical feedback for ongoing sensor maintenance and instrument integration modifications.