Posts Tagged ‘Innovations’

OOI Engineers Develop New Rechargeable Lithium-ion Battery Pack

By John Lund, Research Associate, Woods Hole Oceanographic Institution

The final deployment of the Coastal Pioneer Offshore Mooring (CP04OSPM-00016) was the first deployment of a prototype rechargeable lithium-ion battery pack. The deployment was a success with the battery pack providing power throughout the entire 6.5-month deployment.

Working with Mathews Associates Inc. the OOI engineering team developed a drop-in replacement lithium-ion rechargeable battery pack to replace the original one-time use alkaline packs. Each alkaline pack consists of 72 D-sized batteries that are fabricated into a hexagonal assembly. Nine of these battery packs are fitted into a buoy battery chassis that fits inside the buoy well. The packs are wired together in parallel to provide the required voltage to power the computer (buoy controller) responsible for telemetry and data-logging.

Pioneer moorings are nominally deployed for 6-month intervals. Variability in ship scheduling requires that the buoys be capable of operating for 7+ months. The alkaline battery chassis was designed to fit enough packs to power the buoy for the planned duration and or until the recovery ship arrived.

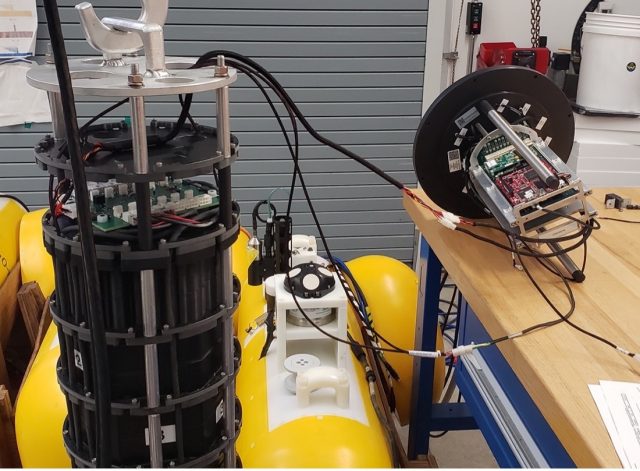

[media-caption path="https://oceanobservatories.org/wp-content/uploads/2023/08/Lithium-batteries.jpg" link="#"]Lithium Battery chassis during testing and integration with the buoy computer. Battery chassis is on the left. Buoy end cap with Linux computer board on the bench. Wire Following Profiler center on the floor collects the majority of the Profiler Mooring data set.[/media-caption]The Offshore mooring was selected to be a test mooring because it is one of the deeper moorings in the New England Shelf (NES) Pioneer Array and as such logs and transmits more data than a shallower mooring. The larger data sets mean that the buoy up-time, and therefore power usage, is greater than one in shallower water so this would be a tougher test of the lithium-ion packs.

Although there is an increased cost to purchasing the initial set of lithium batteries there are many advantages to the rechargeable batteries. Because the alkaline packs are conservatively sized for the deployment there is often a considerable amount of power remaining in the packs when they are recovered, yet this remaining power is insufficient for another full deployment, and new batteries must be used. The chief benefit of the rechargeable batteries will be to keep the one-time use alkaline packs from going to the landfill (~1 ton per year). There is also a considerable labor savings of not having to deconstruct and reload the chassis frames with replacement batteries. Our calculations indicate that we will break in terms of procurement cost compared to alkaline batteries in approximately six years and that the lithium-ion batteries have enough charge cycles (500) to last the duration of the program. With any luck these may be the last batteries we need to purchase for the Profiler Moorings!

Read More

New Controller Latest in OOI Innovations

Having equipment in the water around the clock for six months at a time provides many challenges for the land-based OOI engineering team charged with keeping the equipment operational so there is a continual flow of data to shore. Maintaining consistent, reliable power for the ocean observing equipment is at the top of this list of challenges.

OOI’s data-collecting instruments attached to the moorings run on batteries charged by renewable wind and solar energy. OOI is in the process of replacing the current solar panels with new panels that are more efficient at generating energy, even when shaded. To supplement this upgrade, the OOI arrays are also being outfitted with a brand-new solar controller to manage the energy going into the batteries. Like with the new solar panels, OOI engineers looked for a controller that was available commercially for easier repair and replacement.

“What was important to us was finding a way to use these new solar panels in the best, most optimal way,” said Woods Hole Oceanographic Institution (WHOI) engineer Marshall Swartz. “We looked for a company that would help us specify and build a customized algorithm for a controller that would optimize the functionality of the panels by taking into account battery temperatures.”

[media-caption path="/wp-content/uploads/2021/12/DSC0486-2.jpeg" link="#"]Buoys get quite the workout when they are in the water for six months and more. Powered by wind, solar, and batteries, OOI has recently improved the way energy from the solar panels is managed with new controllers. Credit: ©WHOI, Darlene Trew Crist. [/media-caption]

Some larger, older controllers can consume up to 3-5% of the energy coming into the device, but the new controller is smaller and more efficient, helping to optimize the amount of energy harvested.

Temperature conditions play a big role in how effectively the energy is managed. Changing battery temperatures require the controller to adjust its charge settings to maintain battery life and capacity. The controllers used on OOI moorings sense battery temperature and automatically adjust to assure best conditions to assure reliable operation.

“It’s really essential for us to maintain the proper charge levels for existing temperature conditions,” said Swartz. The OOI buoys encounter a wide range of temperatures: from subfreezing temperatures up to 40°C (over 100°F) when a buoy is sitting in the parking lot before it is deployed. When the buoys are deployed, water temperatures can vary widely from -1 to 33°C (~30 to 91°F), depending on seasonal conditions.

The new controller automatically regulates the amount of electricity going into the battery under such varying temperature conditions. If the wind turbines are generating more energy than the battery needs, for example, the controllers direct excess power into an external load that dissipates heat and adds resistance to the spinning of the wind turbines, preventing the turbines from spinning too fast, possibly damaging their bearings.

“As parts of the OOI infrastructure need replacing or to be upgraded, this offers us the opportunity to find more efficient, and often times, off-the-shelf, less-expensive replacements that will help us keep the arrays functioning and data flowing,” Swartz said. “It’s a winning combination for all parts of the operation.”

Read More