New Controller Latest in OOI Innovations

Having equipment in the water around the clock for six months at a time provides many challenges for the land-based OOI engineering team charged with keeping the equipment operational so there is a continual flow of data to shore. Maintaining consistent, reliable power for the ocean observing equipment is at the top of this list of challenges.

OOI’s data-collecting instruments attached to the moorings run on batteries charged by renewable wind and solar energy. OOI is in the process of replacing the current solar panels with new panels that are more efficient at generating energy, even when shaded. To supplement this upgrade, the OOI arrays are also being outfitted with a brand-new solar controller to manage the energy going into the batteries. Like with the new solar panels, OOI engineers looked for a controller that was available commercially for easier repair and replacement.

“What was important to us was finding a way to use these new solar panels in the best, most optimal way,” said Woods Hole Oceanographic Institution (WHOI) engineer Marshall Swartz. “We looked for a company that would help us specify and build a customized algorithm for a controller that would optimize the functionality of the panels by taking into account battery temperatures.”

[media-caption path="/wp-content/uploads/2021/12/DSC0486-2.jpeg" link="#"]Buoys get quite the workout when they are in the water for six months and more. Powered by wind, solar, and batteries, OOI has recently improved the way energy from the solar panels is managed with new controllers. Credit: ©WHOI, Darlene Trew Crist. [/media-caption]

Some larger, older controllers can consume up to 3-5% of the energy coming into the device, but the new controller is smaller and more efficient, helping to optimize the amount of energy harvested.

Temperature conditions play a big role in how effectively the energy is managed. Changing battery temperatures require the controller to adjust its charge settings to maintain battery life and capacity. The controllers used on OOI moorings sense battery temperature and automatically adjust to assure best conditions to assure reliable operation.

“It’s really essential for us to maintain the proper charge levels for existing temperature conditions,” said Swartz. The OOI buoys encounter a wide range of temperatures: from subfreezing temperatures up to 40°C (over 100°F) when a buoy is sitting in the parking lot before it is deployed. When the buoys are deployed, water temperatures can vary widely from -1 to 33°C (~30 to 91°F), depending on seasonal conditions.

The new controller automatically regulates the amount of electricity going into the battery under such varying temperature conditions. If the wind turbines are generating more energy than the battery needs, for example, the controllers direct excess power into an external load that dissipates heat and adds resistance to the spinning of the wind turbines, preventing the turbines from spinning too fast, possibly damaging their bearings.

“As parts of the OOI infrastructure need replacing or to be upgraded, this offers us the opportunity to find more efficient, and often times, off-the-shelf, less-expensive replacements that will help us keep the arrays functioning and data flowing,” Swartz said. “It’s a winning combination for all parts of the operation.”

Read More

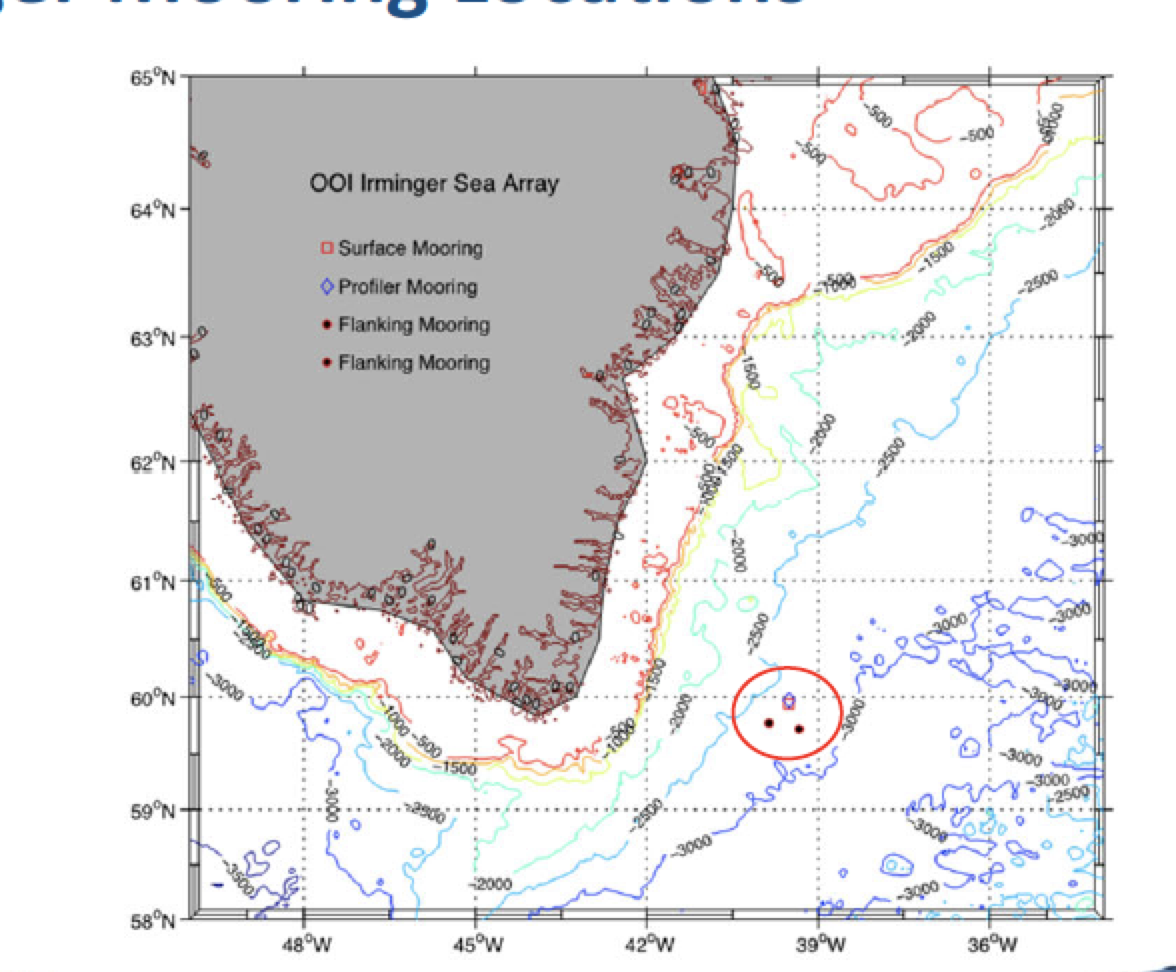

Irminger Sea Array Overcomes Challenging Conditions to Provide Climate Insights

Deployed 140 miles east of the southern tip of Greenland and three miles south of the Arctic Circle, the Irminger Sea surface mooring floats on a cold empty sea named for a Danish naval admiral few people have heard of, in a location that few people could point to on a North Atlantic chart. The Irminger Sea is delineated less by coastlines or geographic basins and more by what is taking place within the deep ocean here, processes only visible with the aid of deep-sea instruments. To oceanographers and climate scientists the region is a confluence of ocean currents where heat carried from the topics gets extracted and cold water sinks into abyss like few other places worldwide and with climate-changing impacts.

Like most high-latitude oceans, storms are frequent and strong. Some storms migrate northeast from the mid-latitudes. Other storms are born here and then mature to impressively violent conditions influenced by the distant high mountains and massive Greenland icecap. Gale-force winds and steep-faced ocean waves spread east over a wide cone from the tip of Cape Farewell. The ice pack around Greenland ejects icebergs, some washing far out to sea where they threaten vessels. Cold air and sea spray build layers of heavy ice on exposed surfaces and instrument sensors. Other oceans can be found with higher waves, some have colder weather, but in few places do storms intensify so quickly, occur as often, and happen in a place so vital to planetary climate. Right where the storm forces are the strongest is also the perfect place for a tower packed with weather instruments.

The Irminger Sea mooring is designed to collect data in this stormy world where meteorological and ocean measurements, especially at the surface, are rare and hard to sustain. The mooring is recovered and a new one put in its place once a year, typically during the short summer month of July when weather conditions are calmest. At more than 4 meters high, the surface mooring tower is heavily instrumented with meteorological sensors and communication antennas, and the surface float is filled with data loggers and redundant computing elements and controllers that collect, store, and transmit data to shore. In total about four tons of floating equipment is anchored to the bottom by a 1.5-mile cable studded with dozens of instruments sampling the deep interior of this sea. To power everything, the buoy float is packed with rechargeable batteries, fueled by solar panels and wind turbines on the buoy tower. Strong winds are usually welcome because they rapidly re-charge the battery packs. Sometimes, however, these can be too much of a good thing.

[media-caption path="/wp-content/uploads/2021/12/Irminger-storm-waves.png" link="#"]Storm waves captured by the Irminger Sea tower camera #5 on 2019-03-19 at 09:01:00 UTC during a typical bad weather day. Observations made by the WAVSS instrument (from 09:00 to 09:20 UTC) report significant wave heights around 5 m (16 ft) and maximum heights of 21 m (69 ft). Records from a second accelerometer (MOPAK) report a wave ~5 m high passing at 09:01 UTC, possibly the same one in this photo. About half-a minute later, at 09:01:30 UTC, the MOPAK recorded a wave >20 m (no image).[/media-caption]

A recent storm during October 18-19, 2021, was one such time. The mooring was battered by wind speeds exceeding 35 knots (gale force) for almost 24 hours, with some topping out above 50 knots. Heavy storm seas built up and stacked upon themselves for hours. At the storm’s peak, about one third of the highest waves were above 15 m (49 ft). Picture heaving an 8000 lb. surface mooring 80 ft up and down on a tilt-a-whirl ride that never stops. Waves this high can bring tons of water crashing down. Towering waves were recorded, some reaching up to 20-25 m (66-82 ft), so high they approached the limits of our instruments.

The Irminger Sea continues to test our ability to “weather harden” instruments in stormy parts of the world. From November to March, daylight is fleeting, the sun hovers near the horizon and solar panels trickle out only a few milliamps. For the next few months, many of the instruments in the ocean interior and on the tower will continue to sample, each instrument powered by its own small battery. The Irminger surface mooring will communicate once each day, a tiny burst of data with vital signs, until spring returns and the sun revives the cold battery packs.

[media-caption path="/wp-content/uploads/2021/12/Ice-near-mooring-.png" link="#"]Ice near the Irminger Sea mooring 2019-04-02. Credit: @WHOI, Peter Brickley.[/media-caption]

The 2021 storm demonstrated, yet again, the challenges of working in the Irminger Sea. Yet, it also demonstrated the remarkable robustness of the OOI moorings in such extreme conditions. Ocean and meteorological measurements gathered by the Irminger Sea mooring during such storm events are extremely valuable for understanding oceanography and climate processes. Equally important is the invaluable experience gained that will drive continued improvement in the accuracy and durability of instruments deployed under such extreme conditions, with consequent increases in knowledge.

Written by Peter J. Brickley, PhD, Senior Engineer, AOPE Dept., Woods Hole Oceanographic Institution and OOI’s Coastal and Global Scale Nodes Observatory Operations Lead

Read More

Shade and Poop at Sea: Increasing Solar Panel Efficiency

Sea lions intermittently visit the Coastal Endurance Array moorings off the coast of Oregon, where they lounge, bask in the sun, and “do their business.” These visits create two problems for the optimum functioning of the instrumented arrays. Because sea lions are heavy, some weighing up to 2,500 pounds, the solar panels upon which they rest need to be strong enough to bear this weight. And, excrement left behind by these itinerant visitors smears and shades the solar panels, making less power available for the ocean observing instrument attached to the arrays.

This intermittent excrement-related shading compounds an existing shading problem caused by the perpetual movement of the moorings. The halos at the top of the moorings cast shadows over the panels below, resulting in a significant power loss. If ten percent of a solar panel is covered in shadow, for example, its output can drop by as much as 70 percent. When sea lions take refuge on the solar panels this loss is exacerbated. Their excrement, at times, can cover up to 30 percent of the panels, virtually wiping out the power generating capability of the panels. Luckily, this coverage results in only a temporary power shortage as wind and seawater ultimately wash away the remains of these visits.

OOI Engineers John Reine and Marshall Swartz of OOI’s Engineering Team put their heads together to tackle these problems. They first addressed the shading issue.

“These moorings are never still,” explained John Reine, Senior Engineer and lead of OOI’s Electrical Refurbishment Team. “In response to wave and wind-driven motion, the masts are always going back and forth, about three times per minute, casting shadows as they move. So this constant movement of shade, no shade, shade, no shade, produces a sort of alternating current from the panels. I went to Marshall and asked how do we fix this?” (John Reine explains the problems and fixes in the video below).

[embed]https://youtu.be/1d6QQJfHqik[/embed]Solar panels are made up of lots of little solar cells, normally connected to each other so the power flows seamlessly from cell to cell. The Engineering Team recognized that by modifying the panel’s internal circuitry, it could easily harvest more of the available light. They proposed a solution to triple the number of bypass diodes, switches that would ignore shaded cells and move the power to the next operational cell in this field of cells. The manufacturer built a prototype based on an high efficiency cell design, inserting additional diodes, and tested the upgraded array. Tests at the manufacturer’s verification facility and at WHOI showed the modified design exceeded expectations.

Timing was opportune. The original solar panels had exceeded their design lifetime and needed to be replaced, but were no longer in production. The team seized on this opportunity to seek out panels incorporating more efficient cells, wired into a circuit proven to minimize shading energy losses, while also bearing the weight of the itinerant visitors.

The task fell to Swartz to find a solar manufacturer able to incorporate the bypass diodes into the panel design. He worked under the proviso that OOI prefers to buy things off the shelf so as to make repair and replacement easy, affordable, and virtually seamless, when needed.

“Such off-the-shelf solutions have worked out well for us,” said Swartz. “As it turned out, we found a supplier, SBM Solar, in North Carolina that does a lot of work with the military, including high-efficiency solar panels. Working with the president and chief engineer of the company, who was very willing to help us customize a product, we came up with a design having a string of 36 cells in the panel. We specified circuitry with bypass diodes so that when any group of four cells gets shaded, they are bypassed and the rest of the cells in the panel can continue to provide unrestricted power to the buoy.

“Just by making this small change, we significantly improved the total energy harvest in a simulated condition by 50 percent, “ Swartz added. What this means in practical terms is that the solar panels can now harvest useful power from almost any light condition –whether it is the reflected light off the surface of the water, low incidence light at sunset, and light that is filtered through the clouds during an early gray day.

Jokingly, he added, “ These panels basically follow the principle of ‘whenever I have the opportunity to make electricity, I’m going to do it’.”

The new panels also passed the weight-bearing problem for the array’s visitors. While the old panels were glass and subject to occasional cracking, the new panels are an aluminum polyester Teflon sandwich, with the solar cells in between the top and bottom layers. This new configuration is much lighter (27 pounds vs 45 pounds for the glass panels), more rugged, and more resilient to the ever-changing at-sea conditions than the glass version it is replacing.

The new panels are also flexible, rather than rigid like glass, which created another challenge to for the Engineering Team. They designed a special back for the panel with struts to provide greater support and more weight distribution as the 2,500-pound visitors flop onto the arrays. The lighter weight of the panels is giving the team more flexibility in placement of the panels on the moorings.

Said Reine, “We are so pleased to have these new and improved “off-the-shelf” solar panels operational. Two panels are now in place on Pioneer Array moorings, and another eight panels have been shipped to the Endurance Array, where they will be greeted by their 2,500-pound interlopers.”

[embed]http://https://youtu.be/1d6QQJfHqik[/embed] Read More

Successful SME Evaluation – Spectrophotometer (OPTAA)

Because of the great diversity of the sensor types deployed by the OOI, it is understood that the familiarity and knowledge of the OOI program scientists and the data team members may not be sufficient to fully investigate and evaluate all types of data being collected. In order to validate the data from these instruments, we reached out to the experts in the field, or as we like to call them “SMEs” (Subject Matter Experts).

For this task, the OOI team asked the SMEs to take a segment of raw data from a specific instrument, and to apply their knowledge and processing tools together with the requisite calibration, sampling, and metadata to produce a calibrated, engineering units version of the data and assess its validity. Assessing validity means answering whether or not the instrument is working properly and yielding data that is realistic. It also means examining whether or not the sampling protocol implemented for the deployment is appropriate to achieve the scientific goals of deploying that instrument.

One of the instruments examined was the WET Labs AC-S Spectrophotometer deployed on the Endurance Array Washington Offshore Surface Mooring on the west coast. Our SME for this instrument was Emmanuel Boss (University of Maine), an expert in the use of optical instrumentation to study the properties of material suspended in seawater.

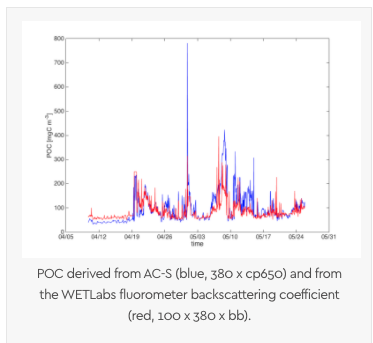

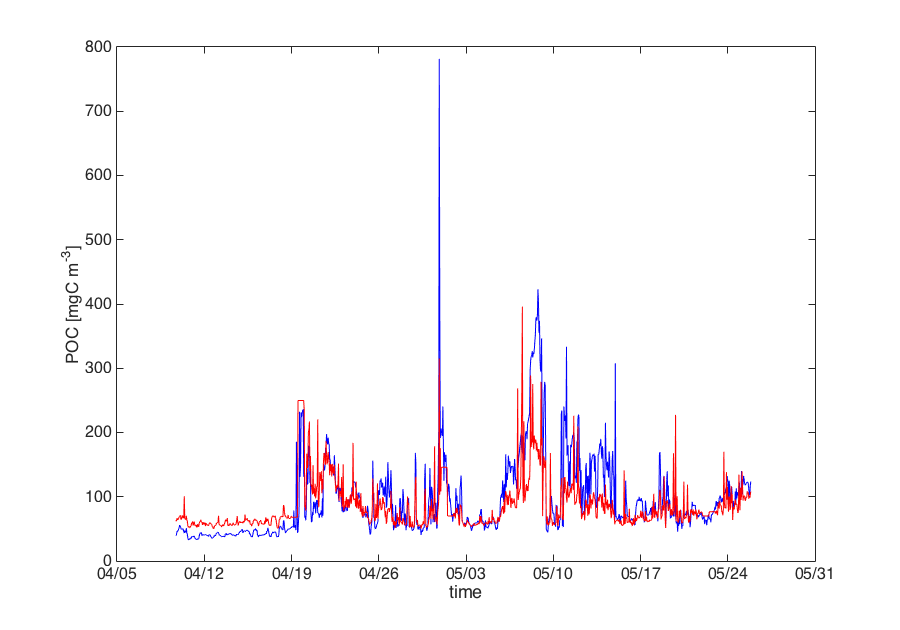

With the data team’s help, Dr. Boss verified 1.5 months of data (April-May 2015) at this site with successful results. He was able to process and plot the data using the raw data and vendor calibration files from the AC-S, salinity and temperature from a collocated CTD data to correct absorption and attenuation median spectra and scattering, and data from a collocated fluorometer to cross-check the chlorophyll and POC results.

Consistency between the sensors suggests that they did not foul during the deployment. Not only did his results show that accurate data was being produced by all the sensors in question, but the AC-S (an extremely sensitive instrument normally deployed for very short periods of time) did not drift noticeably during the deployment period, a notable achievement.

[twocol_one] [caption id="attachment_10536" align="alignnone" width="500"] POC derived from AC-S (blue, 380 x cp650) and from the WETLabs fluorometer backscattering coefficient (red, 100 x 380 x bb).[/caption]

POC derived from AC-S (blue, 380 x cp650) and from the WETLabs fluorometer backscattering coefficient (red, 100 x 380 x bb).[/caption]

[/twocol_one] [twocol_one_last]

[caption id="attachment_10535" align="alignleft" width="500"] Chlorophyll based on AC-S (blue) and on a collocated WETLabs fluorometer (red, calibration x 0.5).[/caption]

Chlorophyll based on AC-S (blue) and on a collocated WETLabs fluorometer (red, calibration x 0.5).[/caption]

[/twocol_one_last]

Dr. Boss stated “The fact that we can do this closure exercise gives me confidence that we should be able to see when fouling or drift become an issue.” He did caution that this analysis represented a very small data set at one location at a specific time, under limited ambient temperature and trophic conditions. “While very encouraging, much more work will need to be done to establish how representative it is,” he noted.

The data team is working on using these results to compare with the processed data being delivered by the OOI software, and are continuing to pursue similar efforts for additional instruments with the help of our other volunteer SMEs. We look forward to being able to tell similar success stories for other OOI instruments.

Read More